HPP technology

Pascalisation and its advantages.

An experienced process in process of democratization

Pascalisation or the HP Processing (HPP) is used to improve the preservation of fresh foods.

Contrary to the traditional processes of preservation in the food-processing industry, the pascalisation do not use a thermal system. It offers to heat sensitive products an interesting alternative compared to the classic heat treatments.

Pascalisation: how does it work ?

The pascalisation (HPP) consists in applying high pressures to fresh foods or drinks in order to stabilize them and increase their shelf life.

This technique created in the 1990s, modifies the structure of molecules and reduces the population of microorganisms.

The pascalisation can also be called cold pasteurization or high pressure processing (HPP).

Advantage of the pascalisation of food and fruit juice

This cold treatment allows micronutriments and aromas not to be degraded.

This technique is particularly relevant in the production of high added value products (thanks to the preservation of the gustative and nutritional qualities). The pascalisation is used on fruit juices, meats, fishes, milk …

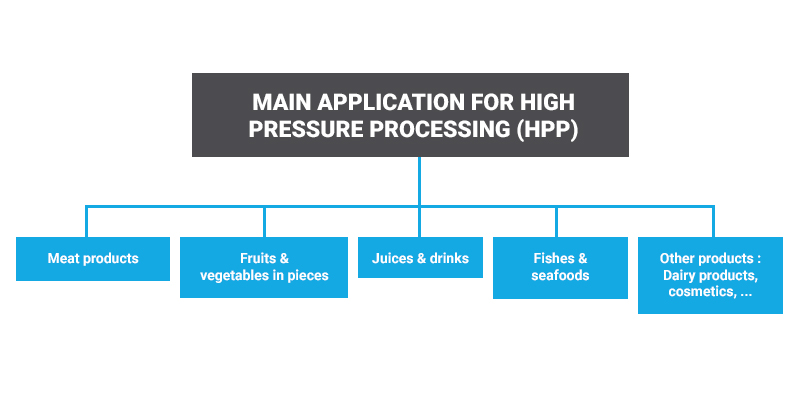

Applications of hpp technology

The applications of Pascalisation, or high-pressure processing (HPP), in the food industry.

This Technology is used for the meat-based products meat and delicatessen, fruits and vegetables in pieces or puree, juices and drinks, seafoods and fishes, as well as some dairy products.